HCT-330SV High Speed LED Pick & Place Machines

High speed LED pick & place machines for LED lighting assembly are purpose-built to assemble LED tube lights, light panels, strip lights, and more, at rates of 36,000 LEDs per hour.

This LED placement machine with ball screw driving is suitable for medium-sized production.

This LED placement machine with ball screw driving is suitable for medium-sized production.

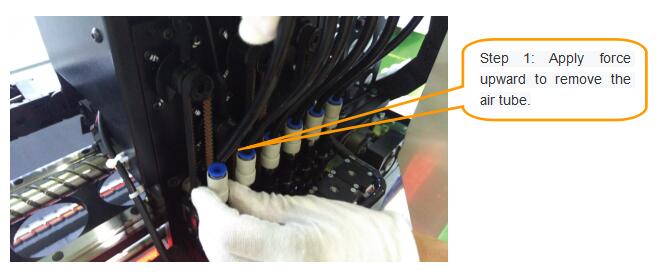

WEEKLY MAINTENANCE - NOZZLE SHAFT CLEANING

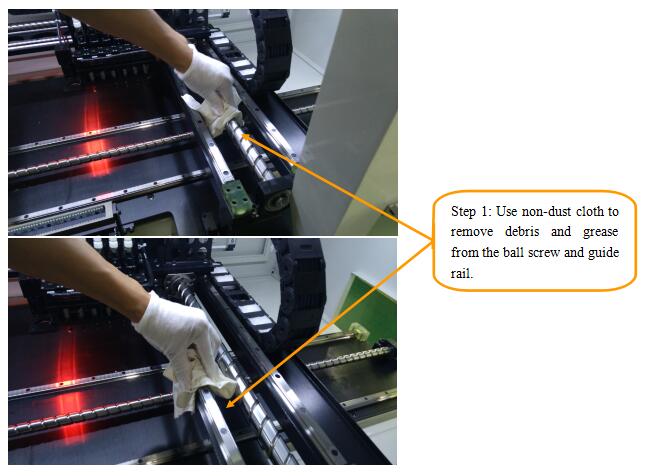

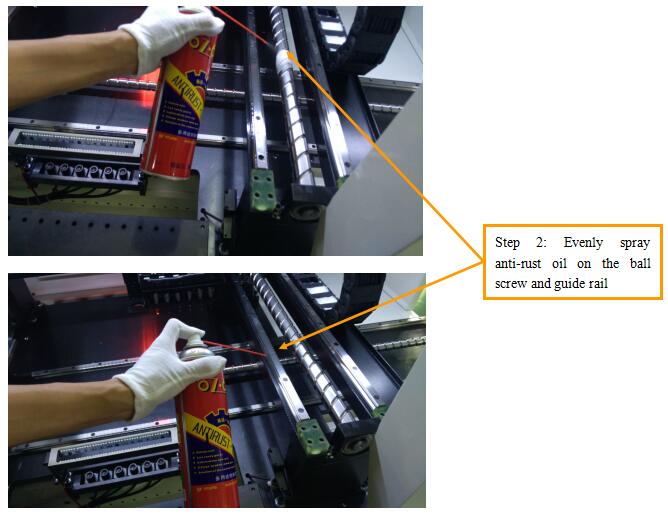

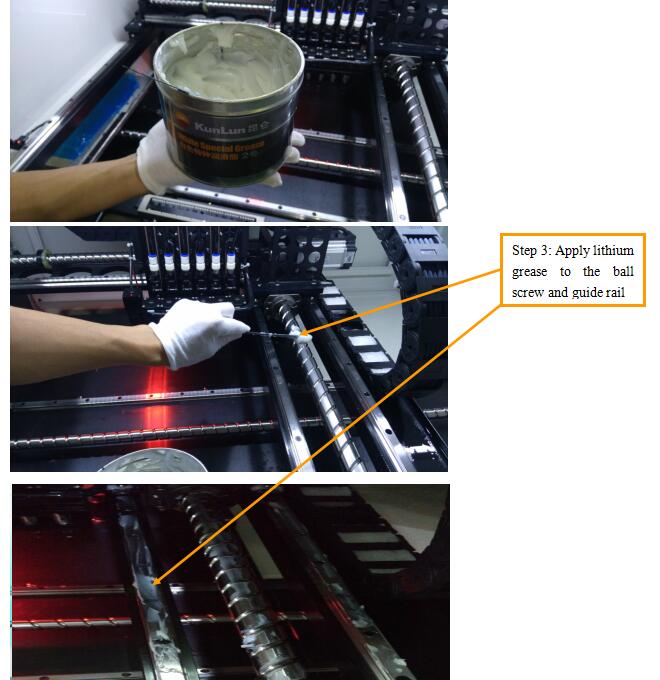

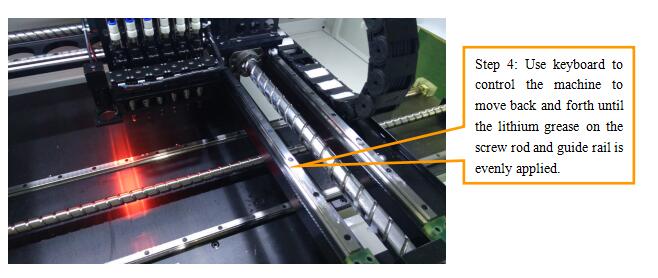

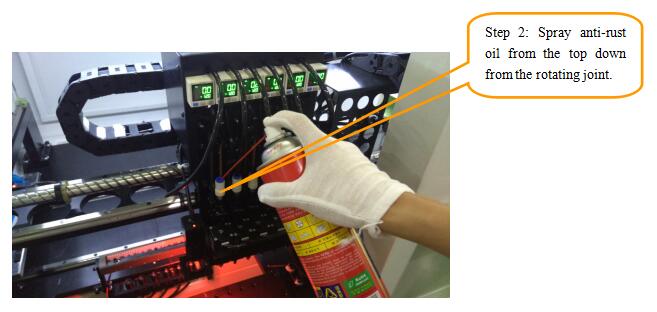

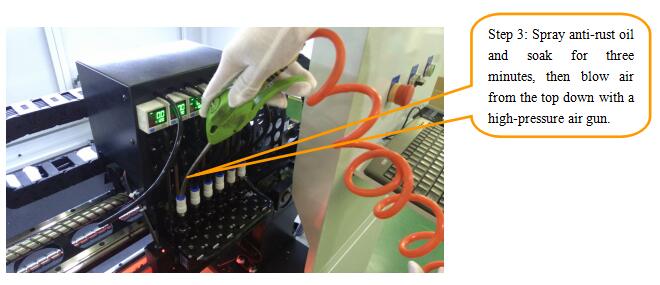

MONTHLY MAINTENANCE - BALL SCREW & GUIDE RAIL CLEANING