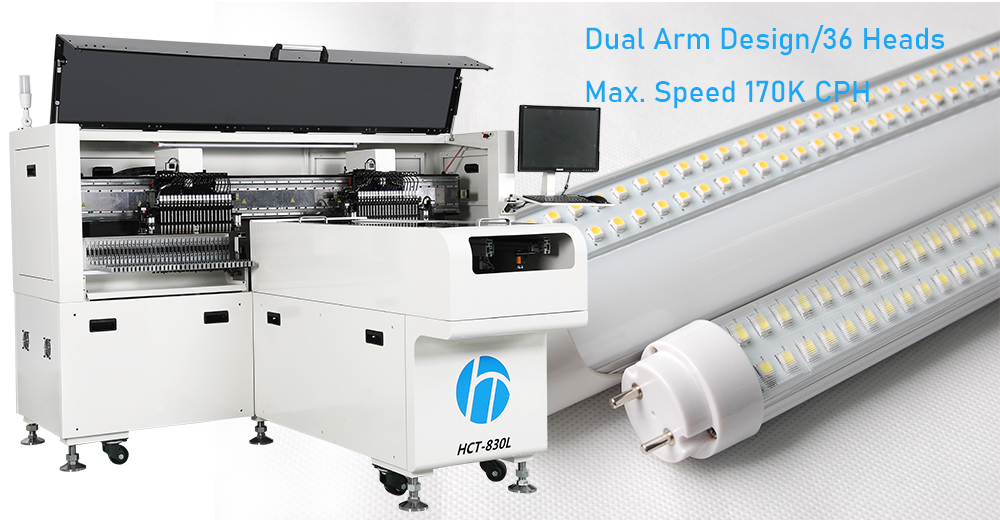

HCT-830L High-speed LED Placement Machine

Dual arm with 36 placement heads, maximum placement speed reaching 170K CPH.

| Model | HCT-830L | |

| Alignment | 5 Sets of Cameras, Mark Correction | |

| Number of Spindles | 36 Spindles x 2 Gantry (Standard) | |

| Placement Rate |

Chip 2835 170000CPH (Optimum) Group Picking & Group Placing |

|

| Placement Accuracy | Chip | ±0.05mm |

| Component Range | Flying Vision |

LED 3014, 3020, 3528, 2835, 5730, 5630, 5050, 7030 and Resistor 0805, 1206 |

| Max Height |

H=8mm |

|

| Board Dimension (mm) | Maximum | 1200(L) x 330(W) |

| Board Handling Method | Inline Conveyor | |

| Tape Feeder | Feeder Type | Electric Feeder |

| Feeder Capacity | 36 (standard 12mm) | |

| Optional | 8mm, 12mm, 16mm. 24mm, 32mm | |

|

Utility |

Power | AC220±20V (50/60Hz, 1 Phase) |

|

Max 2.6KW |

||

| Air Consumption |

0.5-0.7MPa (5.1-7.1kgf/cm2) |

|

| 112.5L/min | ||

|

Mass |

Approx.1,500KG |

|

|

External Dimension(mm) |

2,350(L) x 2,450(D) x 1,425(H) |

|

High Speed LED Production

Dual arm design with 36 placement heads as standard

Maximum placement speed reaching 0.027s/chip.

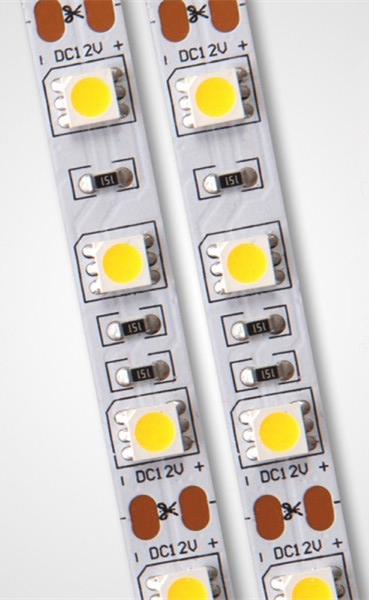

For LED T5/T8, LED panel light, LED strip, LED diffuse reflection, LED outdoor screen of 1.2m long or less.

The number of placement heads can be customized.

PCBs Intelligent Transport

With a SMEMA-compatible inline conveyor

Automatic production line can be figured to save labor and greatly improve efficiency and production capacity.

Automatic width adjustment for conveyor rail, floating clamping PCBs, all for SMT production convenient.

>>>>MORE

Ⅰ. Reinforced applicability to long board: Allows placement of LEDs on large LED lighting PCBs with a maximum length of 600mm/1,200mm.

- Ⅱ. Places SMD components from 0603 to 7474, including resistors.

- Ⅲ. Suitable for all LED tube, LED light bar, LED strip lights, LED display screen P4 and above, and etc.

- Ⅳ. Electric feeders for stable and long-life feeding components.

Ⅴ. Excellent quality hardware support to ensure placement repeatability and precision.

Ⅵ. Self-developed software simplifies production.