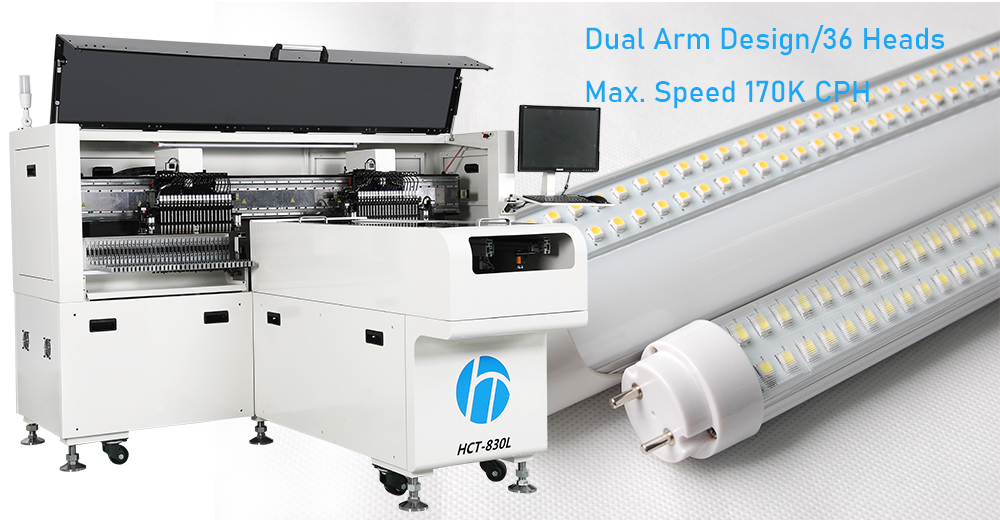

HCT-830L High-speed LED Placement Machine

High Speed automatic placement machine assembles LED PCBs up to 1.2 meters long in a single pass with SMEMA-compatible inline conveyor.

Dual arm with 36 placement heads, maximum placement speed reaching 170K CPH.

Dual arm with 36 placement heads, maximum placement speed reaching 170K CPH.

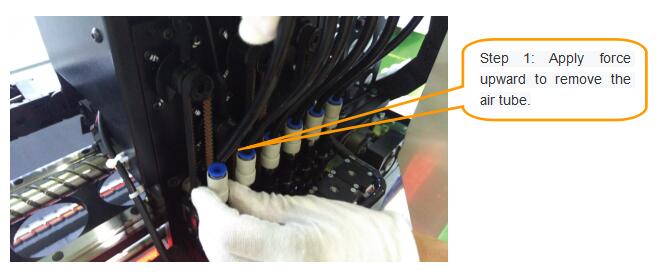

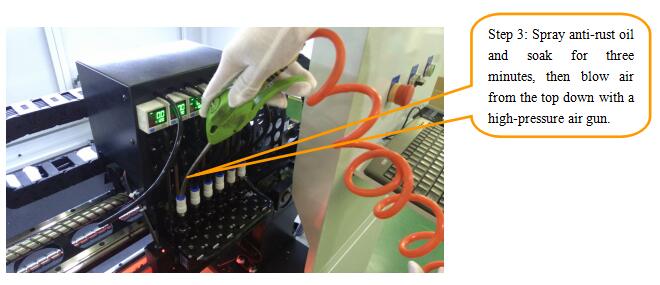

WEEKLY MAINTENANCE - NOZZLE SHAFT CLEANING

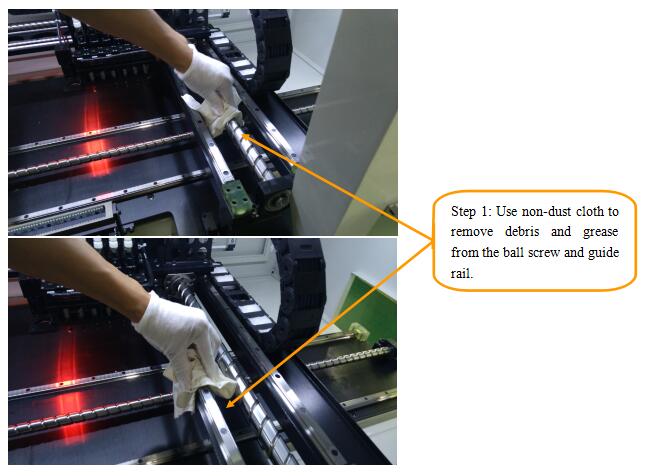

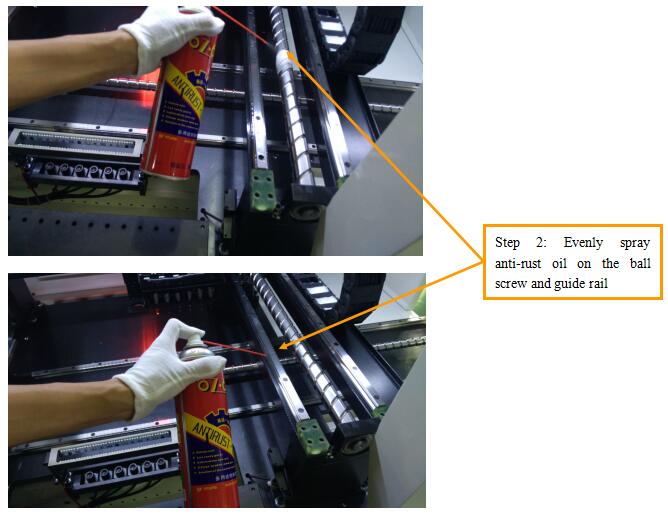

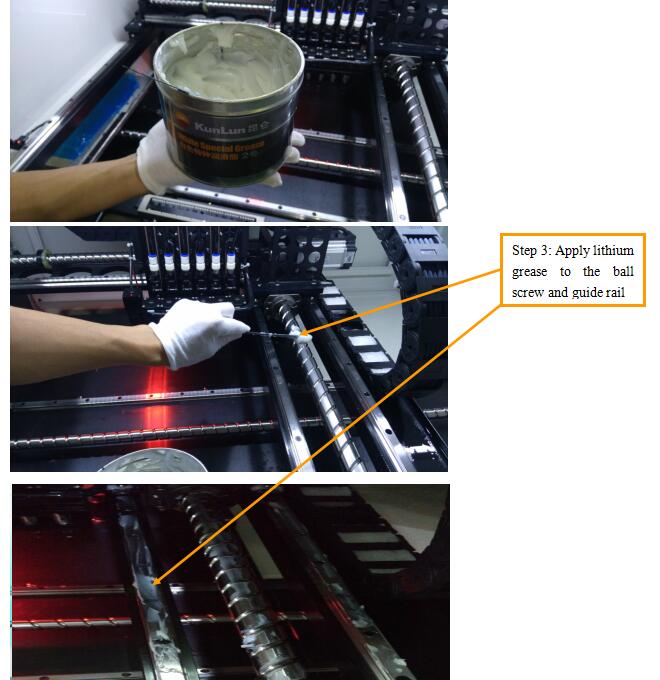

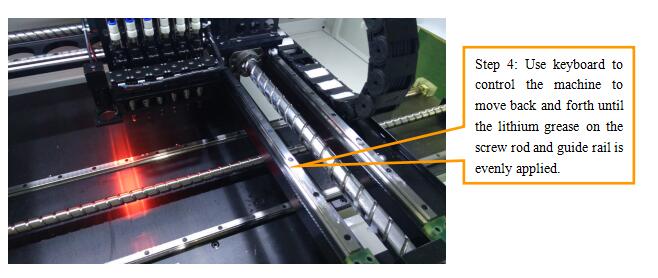

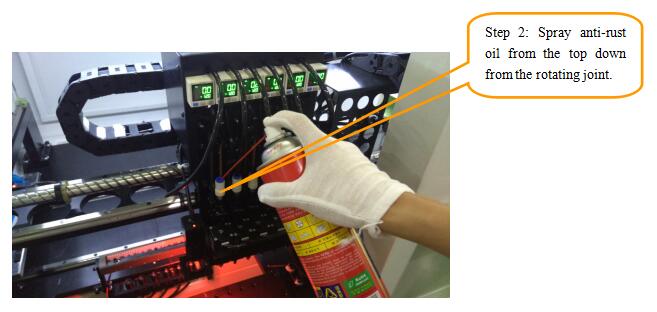

MONTHLY MAINTENANCE - BALL SCREW & GUIDE RAIL CLEANING