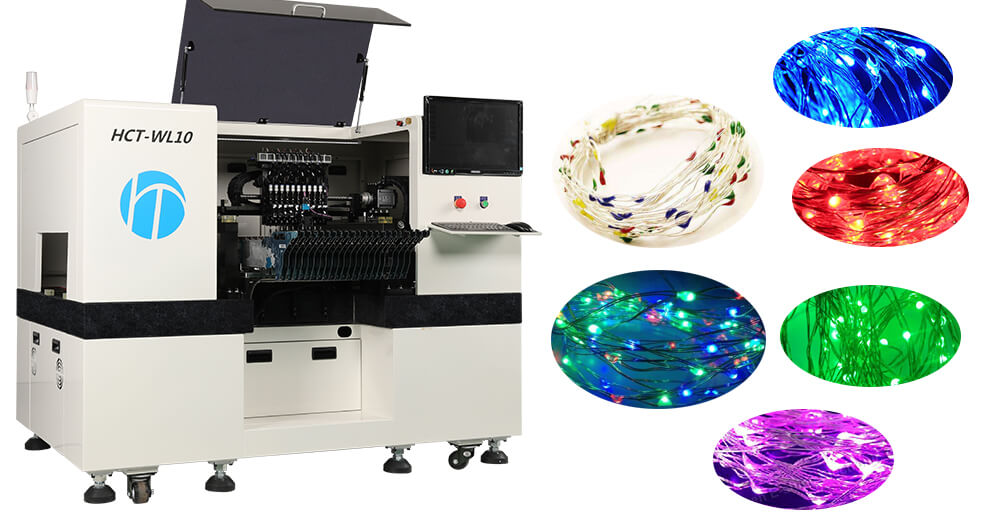

HCT-W10 Automatic Chip Mounter for Copper Wire LED String Lights

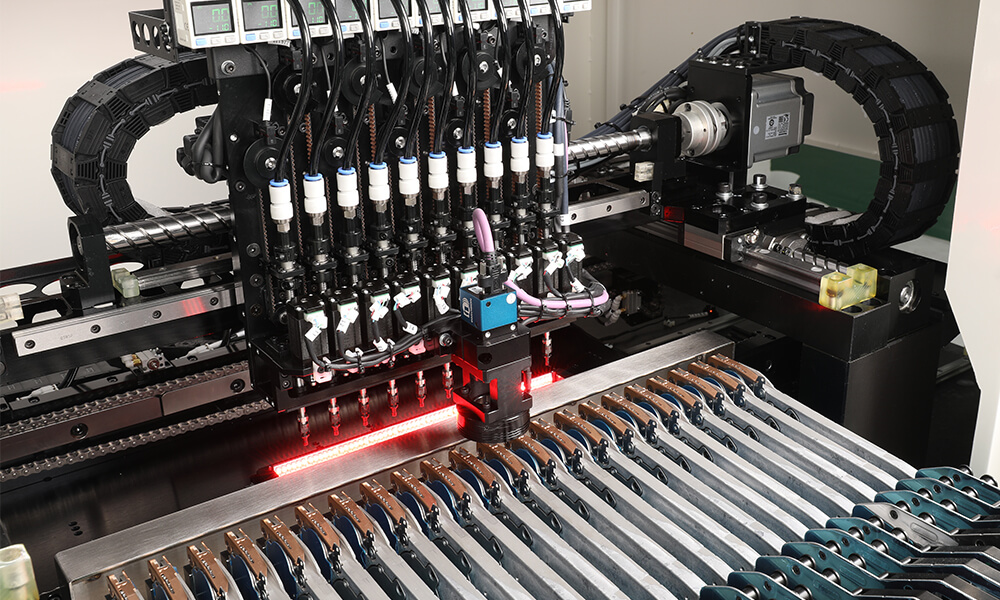

High Speed automatic LED chip mounter are purpose-built to assemble copper wire string lights. With a SMEMA-compatible inline conveyor for production line automation.

There is good mounting capability, high accuracy, reliability and excellent cost performance.

There is good mounting capability, high accuracy, reliability and excellent cost performance.

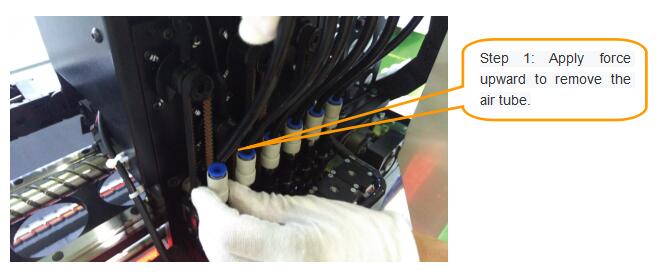

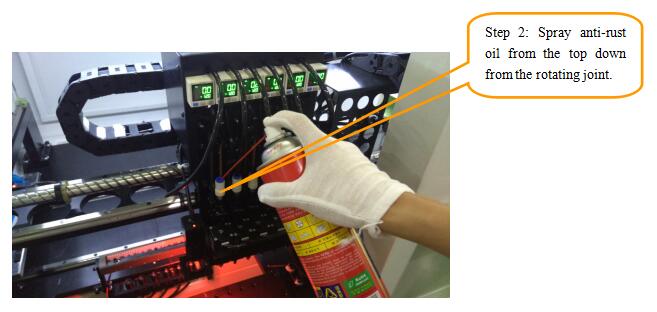

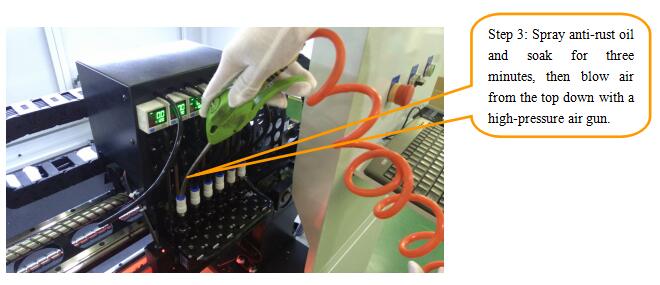

WEEKLY MAINTENANCE - NOZZLE SHAFT CLEANING

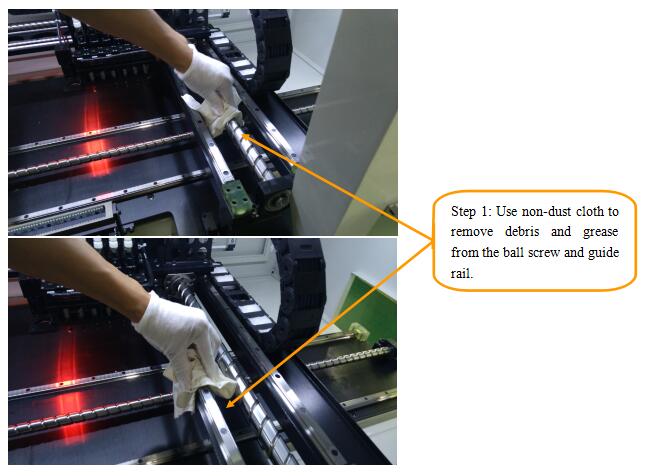

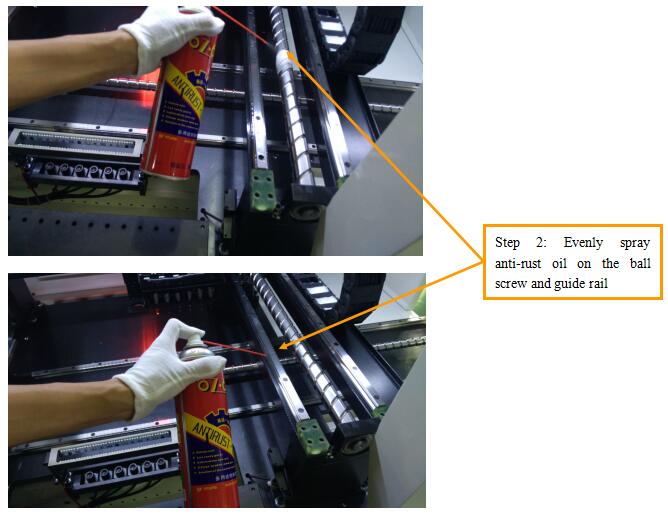

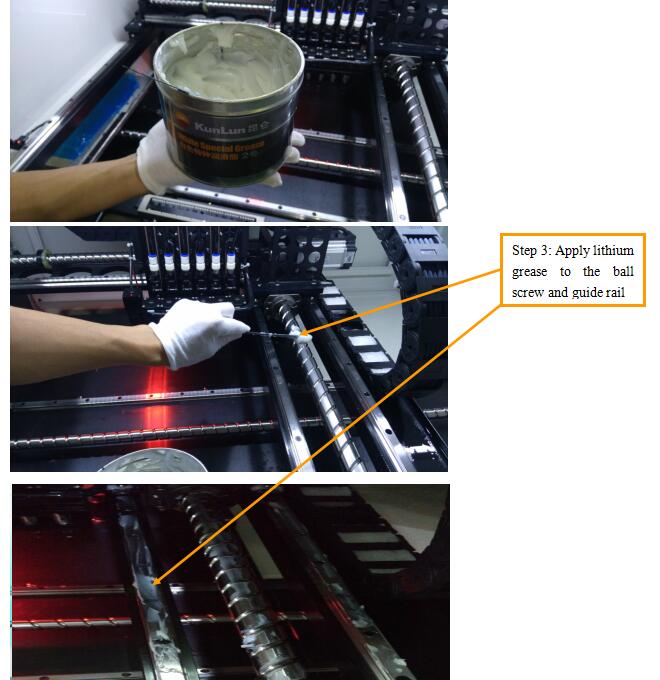

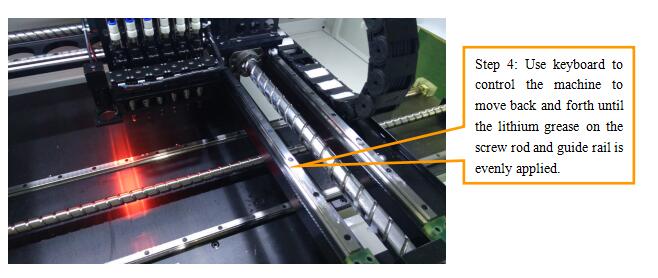

MONTHLY MAINTENANCE - BALL SCREW & GUIDE RAIL CLEANING